Risk management focuses on every production, service, and supply chain process. To help control risk, industries across the board have adopted and continue to employ lean principles in their operational practices. It’s about quick production changeovers, eliminating waste, whether it be from time or materials, reducing variability, improving quality, warding off equipment failures through machine telematics analysis, building reliable supply and delivery networks, and driving more initiatives to continually improve. Leadership in all organizations are focused on building resilience in any process under their managerial domain so it can recover from or prevent any type of disruption.

We see these types of lean initiatives in our own work, in our conversations with other industry executives, in the justification for undertaking a major capital project and in the way maintenance work is proactively planned and scheduled. These factors act as the basis for upgrading and investing in technology. Organizations everywhere strive to remain competitive, increase the value delivered to customers, and decrease their cost of doing business to improve their profitability.All these initiatives make perfect sense because no one can debate that the adoption of lean principles illuminates inefficiencies throughout the organizational value chain. While not newsworthy to us at Utopia, a recent customer survey found that the number one roadblock to lean and organizational improvement initiatives is poor quality data. Managers everywhere cannot achieve the projected results they know are achievable because the data foundation that these initiatives rely on is flawed. These flaws generally arise from incomplete or erroneous information, obsolete facts, duplicate data, unidentifiable material or equipment descriptions, poor quality of asset information, relevant configuration, and more.

It’s been repeatedly documented that data and its accompanying analytics can be the biggest strategic differentiator for successful, high growth companies. Why then, do so many organizations consider expenditures for improving data quality as something that can be postponed?

“In 2016, the Harvard Business Review quoted IBM's in their estimation that poor quality data (https://hbr.org/2016/09/bad-data-costs-the-u-s-3-trillion-per-year) costs businesses $3.1 trillion annually. Even scarier…that estimate was for the US only! How can we justify to our leadership, our executives, and our shareholders our failure to make relatively minor investments in data quality that can have such a significant impact on our businesses?”

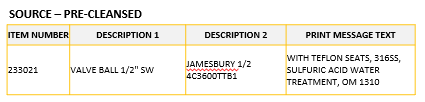

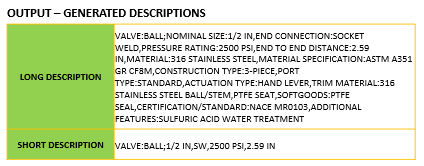

Perhaps the most basic improvement an organization can make to instantly impact its data quality is in the area of material and equipment descriptions and associated attributes. Strong data governance systems like SAP’s MDG (Master Data Governance) can be utilized to automatically create standardized descriptions as well as cleanse existing ones. Supplemented by Utopia’s SAP MDG Enterprise Asset Management and SAP Asset Information Workbench solution extensions, these descriptions can be derived from data and attribute fields that are mapped into auto-generating descriptions (both short and long) that have precise formatting, common abbreviations, key information for searching, and alignment across various business sectors. How much more efficient and productive would your operations if you could easily find equipment, analyze reports, target duplicate records, align capital equipment to the asset register, etc. with data you could trust. See the below, before and after examples for a glimpse of how your data could be rapidly transformed through Utopia’s data quality and governance solutions.

To learn more about how data quality can empower your LEAN program, maximize asset uptime, improve maintenance productivity and take costs out of your business, click here.

To learn more about Utopia’s SAP solutions extensions for asset management, click here.